About Our Company

Dongturbo Electric Company Ltd. (DTEC) is a professional power plant equipment manufacturer and a generator auxiliary inspection & test of the power facilities, (including wind, thermal, solar, friends-star symbol. Hybrid generating units) system solutions provider. Driven by environmental sustainability, DTEC provides a selection of latest products and services that cater to clients across the globe. Boilers, turbines and generators are among its components that DTEC system is focused to design at peak performance and efficiency levels while ensuring protection of the environment. Reputation and Dedication, you can trust as a recognized leader with in the power generation industry, DTEC has become a reliable partner for companies that are seeking to strengthen their power generation capabilities.

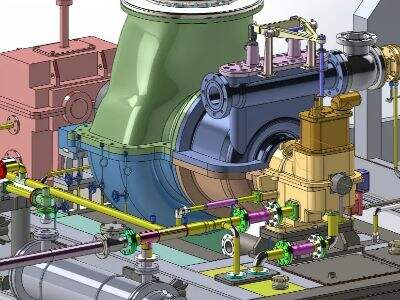

Steam Power Generation Maximize Efficiency with the Drain-Line Heating Solution

In the competitive environment of power production, achieving high efficiency in fossil-fired steam power plants is a pathway to increasing energy capacity. Get more efficiency, lower operating costs, and proven technologies with our STF-DF steam generation plant. Through advanced control systems, monitoring tools and sensors, operators are able to maximize the performance of their plant and improve general efficiency. Modern turbine design and materials also lead to better efficiency and longer operation life. Thus, steam power generation plant can deliver more dependable and sustainable service to the current energy market requirements.

Innovative Solutions for Increased Fuel Efficiency and Lower Cost of Steam Based Power Generation

Steam power generation plants need to remain competitive in the energy market, it is therefore important to improve their fuel efficiency as well as reduce cost. Advanced processes such as integrated gasification combined cycle (IGCC) technology and co-generation can help power plants to optimally use their fuel while at the same time reducing waste. Through advanced combustion technology and utilization of heat recovering systems, a steam turbine generator can produce fuel savings on large scales with cost efficiency. These groundbreaking ideas are not only good for business, but they are better for the bottom line—the environment.

Operational Reliability Enhancement and Environment Optimization in Steam Power Plants

Steam power generation plant operation and environmental sustainability are key concerns for such plants to compete in the market. By developing high-performance predictive maintenance techniques, condition monitoring technologies and predictive analytics plant operators can decrease downtime and increase reliability. Furthermore, incorporation of environmental control devices like flue gas desulphurization and selective catalytic reduction can reduce the emissions level and ensure adherence to environmental legislation. Using advanced technologies and implementing best practices can enable a steam plant to operate at new levels of performance and environmental compliance.

Boosting energy yield and profitability by cutting-edge efficiency measures in steam power generation

In today's highly competitive energy industry, maximizing output/turbine efficiency is critical to success for steam power plants. Operators can also boost performance and output by incorporating state-of-the-art efficiency improvements like advanced steam cycle designs and modernized turbines. Furthermore, productivity and profitability can be improved by implementing hybrid power generation systems including energy storage facilities. Aiming for innovation and lean management, steam power plants enable energy production to be increased, operating costs reduced, while generating more profits in the competitive market.

Maximizing Performance and Decreasing Downtime with Advanced Efficiency Upgrades for Steam Power Plants

To remain competitive among the challenges from an increasingly dynamic energy industry, steam power plants are under pressure to maximize their performance while reducing downtime. Modern efficiency enhancements, such as digital twinning capabilities, next-generation automation systems and real-time monitoring solutions, enable operators to optimize facility performance and address impending problems proactively. By the advanced data analytics and machine learning approach, the performance of steam turbine power plant can be enhanced with reduced maintenance cost and minimized downtime. "By concentrating on efficiency enhancements and technology integration, plant operators can ensure optimal performance and long-term success in the challenging energy market."

Table of Contents

- About Our Company

- Steam Power Generation Maximize Efficiency with the Drain-Line Heating Solution

- Innovative Solutions for Increased Fuel Efficiency and Lower Cost of Steam Based Power Generation

- Operational Reliability Enhancement and Environment Optimization in Steam Power Plants

- Boosting energy yield and profitability by cutting-edge efficiency measures in steam power generation

- Maximizing Performance and Decreasing Downtime with Advanced Efficiency Upgrades for Steam Power Plants

EN

EN

AR

AR

DA

DA

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

RU

RU

ES

ES

SR

SR

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

LA

LA

MN

MN